Regular plant inspections ensure that your water system continues to run safely and the control programme remains effective. Depending on the level of risk, we may suggest that these are carried out on a monthly, or six-monthly basis.

Aqualogic carry out site visits and conduct detailed risk assessments to give an accurate estimate of the risk posed by Legionella bacteria to that site. Testing involves the collection of water samples for thorough analysis, prior to developing a detailed report that indicates your risk factors.

Conducting a Legionella and water quality risk assessment

The primary requirement for determining how to combat the risk of waterborne bacterial infection is the risk assessment survey. After a site visit, sample gathering and water testing are complete, we follow a carefully developed process to generate a detailed report highlighting important details, which assist building managers to put the correct measures in place.

Our thorough reports communicate to building managers and those employed to deal with the water services, the extent of the water system. Drawn up in colour using Microsoft Visio, we identify those elements of the system where Legionella may grow, as well as showing how the system functions. Where a higher level of detail is required we can carry out a full survey of a building’s plant, pipe work and outlet location.

Information provided on your water quality assessment

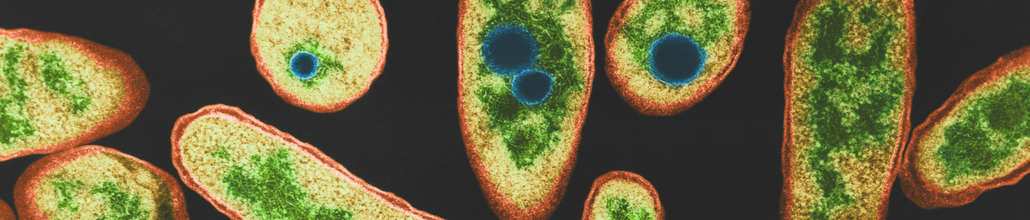

The importance of microbiological testing

Regular microbiological testing is an effective means to verify that your water system hygiene measures are effective and to identify areas of the water system that may pose particular risks.

Our laboratory’s UKAS accreditation guarantees the reliability and quality of Legionella, Pseudomonas and general microbiological tests that are used as indicators of your water safety.

Results are archived for reference and these records contribute to the robust water safety programmes we implement and manage. At our clients’ request, we can retain analytics so that further investigation of the samples can be entered into at a later date, if required.

The frequency at which you will require a TMV check will depend on factors such as water hardness and how often it is used – we conduct regular maintenance checks to ensure that your TMV continues to operate at the optimal temperature of between 39-43°C. During servicing, we will check the operation of the valve and clean, descale and disinfect the strainers. Regular maintenance is vital not only to ensure that your TMV is still working, but to guard against any dirt that could lead the growth of Legionella and other waterborne bacteria. Legionella grows and multiplies in water temperatures that are between 20 – 45ºC, but is killed when temperatures exceed 60ºC. Naturally though, using water at this high temperature would be unsafe for skin contact and would result in scalding – once water hits 50 ºC it takes significantly less time in contact with skin to result in third-degree burns. By installing a TMV, water can be stored at this high temperature known to prevent the growth of Legionella, but delivered safely to the skin once is passes through a cold water system just prior to reaching the tap.